Are you tired of struggling with ceramics that are difficult to machine and don't meet your high-quality standards? Look no further than Itowu ceramic - the solution to all your machining problems. In this blog post, we'll explore the benefits of using Itowu ceramic for your next project and how it can help take your manufacturing processes to the next level. So buckle up and get ready to discover why Itowu is the go-to choice for quality machinable ceramics!

What is machinable ceramic

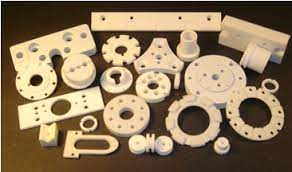

Machinable ceramics are a versatile type of ceramic material that can be machined into various shapes. Itowu's machinable ceramics have gained popularity in different industries like Aeronautics industry, Fluid control, Food industry, Automobile Industry, High-temperature environment, Electronic Information and Communication, Metallurgy, Biomedicines, Semiconductor, Glass, and Machinery manufacturing.

Why choose Itowu

Itowu offers customized services to customers, such as fast quotes, small quantities available, technical support during the manufacturing process, and various packaging options. We also provide free consulting service to help customers find the most suitable application material.

Itowu specializes in the production of nitride materials in China with over 300T. Nitride materials have a wide range of applications and are used in various industries because they have many superior properties compared to metal materials, such as wear resistance, thermal performance, high strength, and low density.

Silicon nitride is known as the "King of engineering ceramics" and is suitable for a variety of different and complex working environments. It has excellent hardness, wear resistance, chemical stability, high strength, corrosion resistance, light-weight, and good thermal conductivity. Aluminium nitride is another type of high thermal conductivity ceramic material that has a promising application prospect. It has high thermal conductivity and heat dissipation, insulation, and high-temperature resistance.

Boron nitride is a crystal composed of nitrogen and boron atoms and is known as "white graphite." It has good heat resistance, thermal stability, thermal conductivity, high-temperature dielectric strength, and is an ideal heat dissipating material and high-temperature insulating material. It can be processed into various shaped parts and is not wetted with aluminum water, providing comprehensive protection for the surface of materials in direct contact with molten aluminum, magnesium, zinc alloy, and its melting slag.

Itowu conducts quality control and production management strictly in reference to the ISO9001 quality management system and follows the requirements of ISO14001 to handle the relationship between self-development and environmental protection, carrying out effective pollution prevention and achieving sustainable and benign development.

Conclusion

In conclusion, Itowu nitride ceramics are gaining popularity in various industries because of their superior properties compared to metal materials. We offer customized services to our customers, providing them with the most suitable application material, and technical support during the manufacturing process. With mature, advanced production technology, rich experiences, professional researching teams, and sales teams, Itowu has become a trusted brand in the market.