TECHNOLOGY

Nitride Materials And Products

Nitride materials have a wide range of applications.

Silicon nitride: high temperature resistance, well chemical stability ,high strength, hardness, wear resistance, impact resistance, corrosion resistance, light weight, good thermal conductivity;

Aluminium nitride: high thermal conductivity and heat dissipation, insulation, high temperature resistance, it’s kind of high thermal conductivity ceramic material which has a very promising application prospect;

Boron nitride: high temperature resistance, non-bonding, corrosion resistance, heat dissipation and thermal conductivity. It is not wetted with aluminum water, and can provide comprehensive protection for the surface of materials in direct contact with molten aluminum, magnesium, zinc alloy and its melting slag;

Nitride ceramics is a general term for multi-purpose compounds. Since technical ceramics manufacturing have many superior properties to metal materials, such as wear resistance, thermal performance, high strength, low density, etc., many industries use technical ceramics in their operations.

The application of ceramic materials is wide. Nitride machinable ceramics can be used in everyday life, such as bearings for bicycles, artificial knee, and hip joints, flat panel displays, cosmetics, durable parts for small home appliances, LED lights, ceramic igniters for gas appliances, precision blades.

After reading this short science article, you will realize that machinable ceramic materials will change production and life now and in the future.

Let us introduce you about the application areas of utilizing Nitride machinable ceramics.

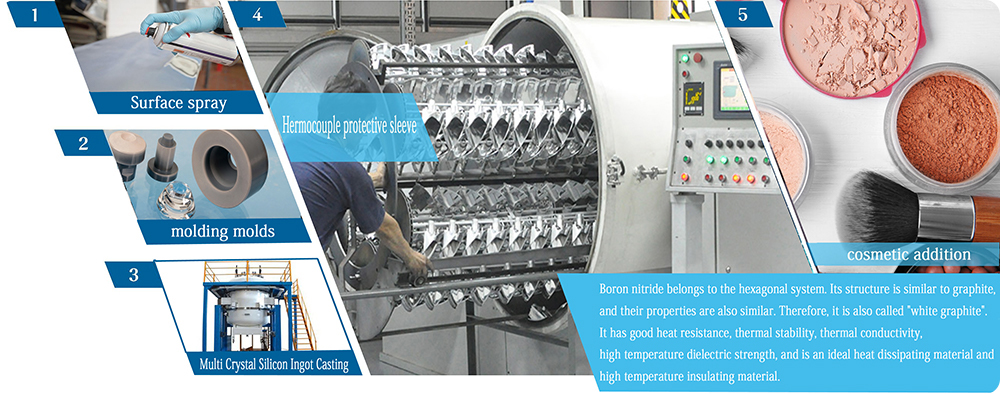

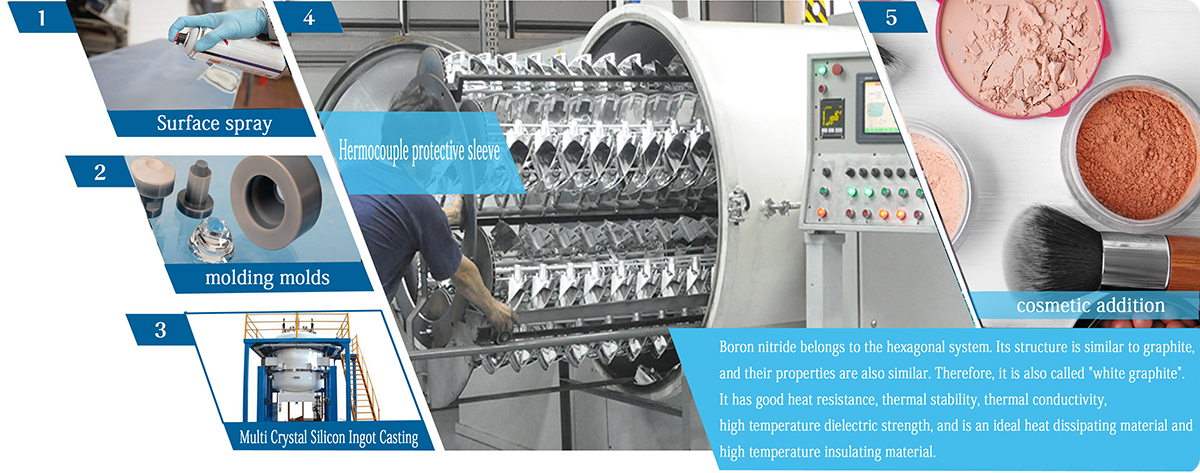

Boron nitride is a crystal composed of nitrogen and boron atoms. The crystal structure is divided into hexagonal boron nitride(HBN), close-packed hexagonal boron nitride(WBN)and cubic boron nitride. The crystal structure of hexagonal boron nitride has a similar graphite layered structure, which presents a white powder of loose, lubricated, moisture absorption, light quantity etc. It is also known as” white graphite”. The theoretical density is 2. 27g/cm³, the proportion is 2.43, and the Mohr hardness is 2.It has good heat resistance, thermal stability, thermal conductivity, high temperature dielectric strength, and is an ideal heat dissipating material and high temperature insulating material. can be processed into various shaped parts.

1. Operating temperature: 1900 ℃ in vacuum, 2100 ℃ in the case of nitrogen, argon and other inert gases, and 900 ℃ in the case of oxidation resistance.

2. It has extremely strong thermal shock resistance and can be cooled rapidly for 15 minutes at 1000 degrees to room temperature for 100 times without cracking.

3. It has good corrosion resistance, good chemical stability and small thermal expansion coefficient.

4. Excellent electrical performance: excellent insulation at high temperature, which will not significantly decrease with the increase of temperature. The breakdown voltage is 3KV/MV, the low dielectric loss is 2.5 x 10-4 at 108HZ, and the dielectric constant is 4, which can penetrate microwave and infrared ray.

5. With many metals, glass solution does not bond does not react.

6.The expansion coefficient of hexagonal boron nitride is equivalent to that of quartz, but the thermal conductivity is ten times that of quartz.

7.It also has good lubricity at high temperature.

8.Hexagonal boron nitride is insoluble in cold water, when water boils, it hydrolyzes very slowly and produces a small amount of boric acid and ammonia.

9. Production process : hot pressing.

*Name: Boron Nitride

*Molecular weight:24.18( According to 1979 international CAS CODE:10043-115 atomic weight)

*HSCODE: 2850001900

*Quality Standard: Enterprise Standard (Q/YLH001-2006)

*Molecular formula: BN

*Name: Boron Nitride

*Molecular weight:24.18( According to 1979 international CAS CODE:10043-115 atomic weight)

*HSCODE: 2850001900

*Quality Standard: Enterprise Standard (Q/YLH001-2006)

*Molecular formula: BN

Our products are mainly used in LED packaging, microelectronics, automotive electronics, high-power power electronics template, RF RF microwave communication, aerospace and other fields.

“Extreme” high thermal conductivity.

The thermal conductivity of aluminum nitride ceramic is the highest in all ceramic materials; similar to aluminum and more than 6 times higher than Alumina.

High electrical insulation capacity.

Aluminum nitride ceramic has good insulation, low dielectric loss characteristic. Its thermal expansion is close to that of silicon.

Dense and No toxicity.

The aluminum nitride is non toxic and is considered to replace the Beryllium oxide (BeO) in the semiconductor application and substrates.

Silicon nitride ceramics is known as the “King of engineering ceramics” and is suiuable for a variety of different and complex working enviroments.

Performance/ Advantage:

1.Super hard and wear resistant.

2.High and low temperature resistance.

3.Corrosion resistance

4.Non-magnetic electrical insulation

5.High thermal conductivity and low expansion coefficient.

1. Application of Ceramic Materials in the Solar Industry

The solar industry has witnessed significant advancements with the integration of technical ceramics manufacturing and machinable ceramics. Technical ceramics, including machinable ceramics, have emerged as essential materials in various solar applications, improving efficiency and durability. Nitride ceramics are widely used materials in the solar industry. Our products include solar panels, solar panels, and solar cells.

2. Application of Ceramic Materials in the Aerospace Industry

The properties of machinable ceramics make them ideal materials for aerospace applications. It has the advantages of lighter, electrical insulation, high temperature, corrosion, corrosion, and wear resistance.

Electrical Application of Ceramic Materials

Electronic components such as sensors, capacitors, resistors, and antennas are becoming smaller and more powerful with advanced and machinable ceramic materials.

Structural Application of Ceramic Materials

Structural ceramics are used as thermal barrier coatings (TBC) in the hot parts of engines. Additionally, these materials are used as matrices in machinable ceramic matrix composites (CMC). Lightness and strength are the main factors for using machinable ceramic composites.

Machinable ceramics are lighter than most metals and can withstand high temperatures, properties that lead to structural ceramics being used in aerospace components.

3. Application of Ceramic Materials in the Automotive Industry

Machinable ceramics are used in transportation mainly because of their advantages, such as light weight, high-temperature resistance, heat insulation, wear resistance, corrosion resistance, safety and reliability.

Especially the excellent durability and high-temperature resistance are the main reasons for its application.

Machinable ceramic components used in the automotive industry include:

Functional ceramics include glow plugs, sensors, spark plugs, heaters, fuel injection systems, etc.

Structural ceramics include catalyst carriers, filters, brake discs, pumps, etc.

Water-cooled pumps are used in hybrid vehicles to cool critical engine electronics, and lithium-ion batteries use precision-engineered ceramic shafts and bearings. Exhaust pipes protect the vehicle's engine management system from engine heat. The machinable ceramic material blocks heat from the exhaust holes.

4. Application of Ceramic Materials in the Electronics Industry

This industry is so huge that it relies on technical ceramics. Smartphones, computers, and TVs used daily machinable ceramic components. The properties of insulation, semiconductor, superconductivity, magnetism, and piezoelectricity make technical ceramics manufacturing play an important role in the electronics industry.

Technical ceramics manufacturing products are now common components. A wide range of electrical conductivity and magnetic properties characterize these machinable ceramic materials. Compared with metal materials, products can be miniaturized and cost-effective.

Power Electronics

Machinable ceramic components in power electronic products include vacuum switching tubes, diodes, and surge arresters. It is widely used because of its high reliability and long service life. Another advantage is that high-temperature resistance can be miniaturized to achieve a high vacuum airtight environment and has oxidation resistance.

Electronic Sensor

Machinable ceramic sensors can meet the demanding requirements of machinery and equipment. Such devices mainly monitor non-electrical variables, such as temperature, pressure, distance, moisture content, and gas concentration, and convert them into electrical signals.

Wafer Products

In semiconductor technology, large-scale substrates made of machinable ceramic materials are often used to hold wafers.

5. Application of Ceramic Materials in Engineering Areas

Marine Engineering

Equipment in this industry needs to operate under extreme conditions, such as on the deep seabed. Technical ceramics manufacturing products can withstand high pressure, variable loads, corrosion resistance, wear resistance, and impact resistance. The characteristics of high customizability can easily meet such requirements.

Masonry Projects

Machinable ceramic products in the construction industry include cement and cement-based materials, which are used to make mortar and concrete. In addition to water, sand, and cement, concrete also contains gravel and small stones, which provide the mix with strength.

6. Application of Ceramic Materials in the Healthcare Industry

Machinable ceramic materials have a series of special features. They are very suitable for application in the medical field, such as temper, non-toxic, hardness, high-pressure resistance, low friction coefficient, and sterility.

Bioceramics and Dental Ceramics

Bioceramics are mainly used in medical implants, such as hip, knee, joint, and craniofacial hard tissue. Dental ceramics, including braces, crowns, bridges, and all-ceramic roots, have better osseointegration capabilities than metals (titanium) through using machinable ceramic materials.

Instruments and Tools

Including engineering brackets; medical pumps; drug delivery devices; piezoelectric elements; ceramic components for imaging equipment.

7. Application of Ceramic Materials in Personal and Families

The unique properties of technical ceramics manufacturing products include the ability to operate at high temperatures, high strength, electrical insulation, wear and corrosion resistance. It has various applications in household appliances, including electric heaters, grills, small appliances (microwave ovens, coffee machines), igniters for gas and electrical systems, LED lighting, precision blades, etc.

8. Application of Ceramic Materials in the Food Processing Industry

Technical ceramics manufacturing plays a crucial role in the food processing industry, contributing to improved efficiency, hygiene, and safety in food production processes. Due to their food safety properties, technical ceramics are also ideal for the food service industry and can be used in any environment in a food production line where food-grade safety is required, such as dosing units, dosing slides, valve guides,, and seats, stops and clamps and forming molds.

9. Application of Ceramic Materials in Chemical Areas

Chemically inert ceramics offer excellent corrosion resistance and durability in chemical handling applications. Components are manufactured using corrosion-resistant materials to meet a variety of advanced chemical processing needs. Includes: Silicon Nitride Crucibles, Boron Nitride Crucibles, and custom assemblies.

When you need high-quality machinable ceramic materials or components and want to ensure reliability and durability, you need to cooperate with experienced technical ceramic manufacturers, such as Itowu. Technical ceramics manufacturing plays a vital role in meeting the diverse needs of industries by producing high-performance ceramic components.

We are a leader in the quality of technical ceramic materials, and our engineers can advise whatever you need. Contact us via yvonne@i-towu.com, or call + 86 15640969516.

We are looking forward to collaborating with you.