NOZZLES

NOZZLES

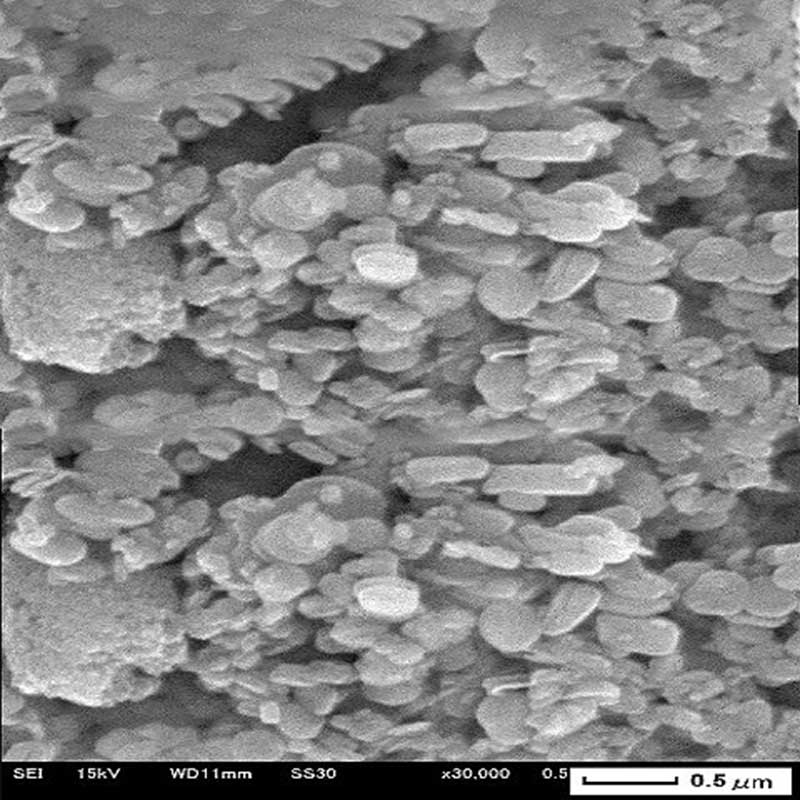

Categories BN Compound Ceramic, Boron Nitride

Boron Nitride Compound Ceramic

1. The optimized formula and unique process make it highly resistant to thermal shock and high-temperature creep. Maximum using temperature 1700 ℃.

2. Low thermal expansion coefficient, no cracking or deformation during use.

3. Strong erosion resistance, wear resistance and metal corrosion resistance. Long service life.

4. Good raw materials, process control, product stability.

PRODUCT DESCRIPTION

1.Powder Metallurgy

2.Metal Casting

3.Insulators for High Temperature Furnace

4.Crucibles for Metal Evaporation

5.Parts for Melting Metals or Glass

6.Casting Molds for Metal or Alloy

7.High Temperature Support Parts

8.Transport Pipes or Nozzles for Melting Metal

Product Description

| Grade Typical Value | BN-B | BN-C | BN-D | BN-E | |

| Purity (%) | BN+Zr+Al | BN+SiC | BN+Zr | BN+AlN | |

| Color | Gray white | Gray green | Gray white | Gray green | |

| Density (g/cm3) | 2.25-2.35 | 2.40-2.50 | 2.80-2.90 | 2.80-2.95 | |

| Oxygen content (%) | - | - | - | - | |

| Volume resistivity (Ω・cm) | >1013 | >1012 | >1012 | >1013 | |

| Operating temp (℃) | Air | ≦1000 | ≦1000 | ≦1000 | ≦1000 |

| Inert gas | ≦1750 | ≦1750 | ≦1800 | ≦1800 | |

| Vacuum | ≦1750 | ≦1750 | ≦1800 | ≦1800 | |

| Bending strength (MPa) | 65 | 80 | 90 | 90 | |

| Coefficient of thermal expansion (10-6/℃) | 2.0 | 2.8 | 3.0 | 2.8 | |

| Thermal conductivity (W/m・K) | 30 | 40 | 30 | 85 | |

Get A Quote