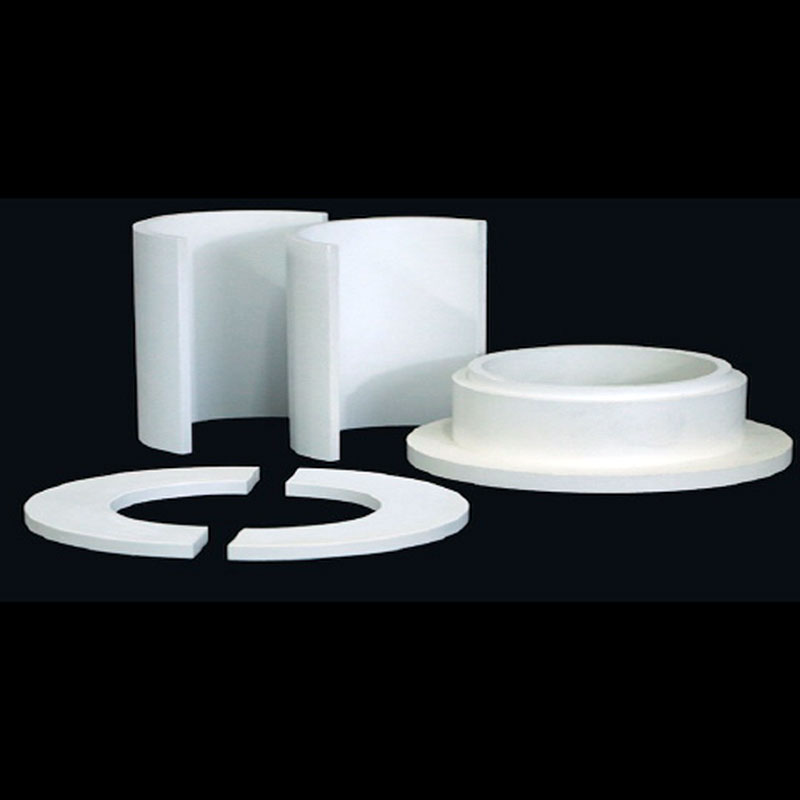

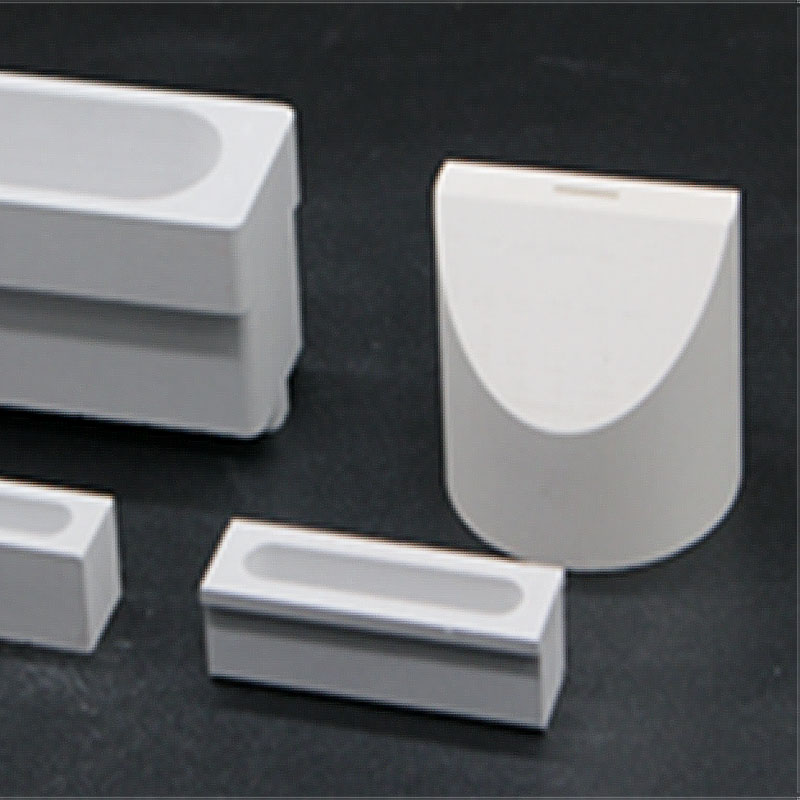

COATING-CRUCIBLES

COATING-CRUCIBLES

Categories BN Compound Ceramic, Boron Nitride

Boron Nitride Compound Ceramic

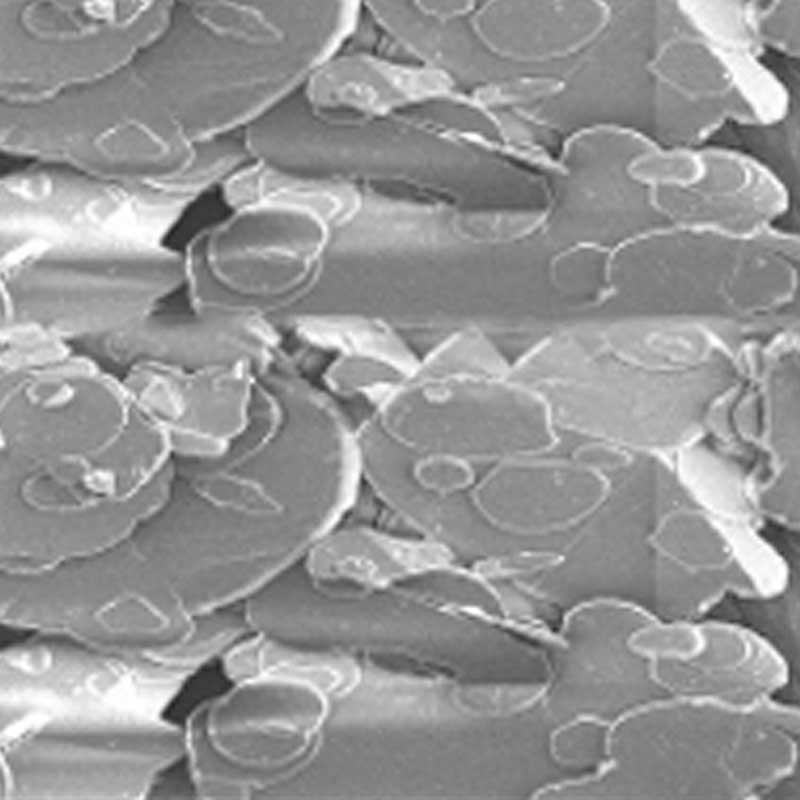

1. Independently developed new formula products in order to solve the problems of sputtering pot and nickel and copper corrosion.

2. Adopt advanced formulation technology, optimize components, have good chemical stability and stable resistivity.

3. Good oxidation resistance, resistant to aluminum, nickel, copper and gold corrosion.

4. The maximum using temperature is 1800 ℃.

Performance index

| Grade Typical Value | BN-B | BN-C | BN-D | BN-E | |

| Purity (%) | BN+Zr+Al | BN+SiC | BN+Zr | BN+AlN | |

| Color | Gray white | Gray green | Gray white | Gray green | |

| Density (g/cm3) | 2.25-2.35 | 2.40-2.50 | 2.80-2.90 | 2.80-2.95 | |

| Oxygen content (%) | - | - | - | - | |

| Volume resistivity (Ω・cm) | >1013 | >1012 | >1012 | >1013 | |

| Operating temp (℃) | Air | ≦1000 | ≦1000 | ≦1000 | ≦1000 |

| Inert gas | ≦1750 | ≦1750 | ≦1800 | ≦1800 | |

| Vacuum | ≦1750 | ≦1750 | ≦1800 | ≦1800 | |

| Bending strength (MPa) | 65 | 80 | 90 | 90 | |

| Coefficient of thermal expansion (10-6/℃) | 2.0 | 2.8 | 3.0 | 2.8 | |

| Thermal conductivity (W/m・K) | 30 | 40 | 30 | 85 | |

Get A Quote